Safer Alternatives to IPA for Resin 3D Printing Cleanup

May 13, 2025

Written by: Vertec BioSolvents

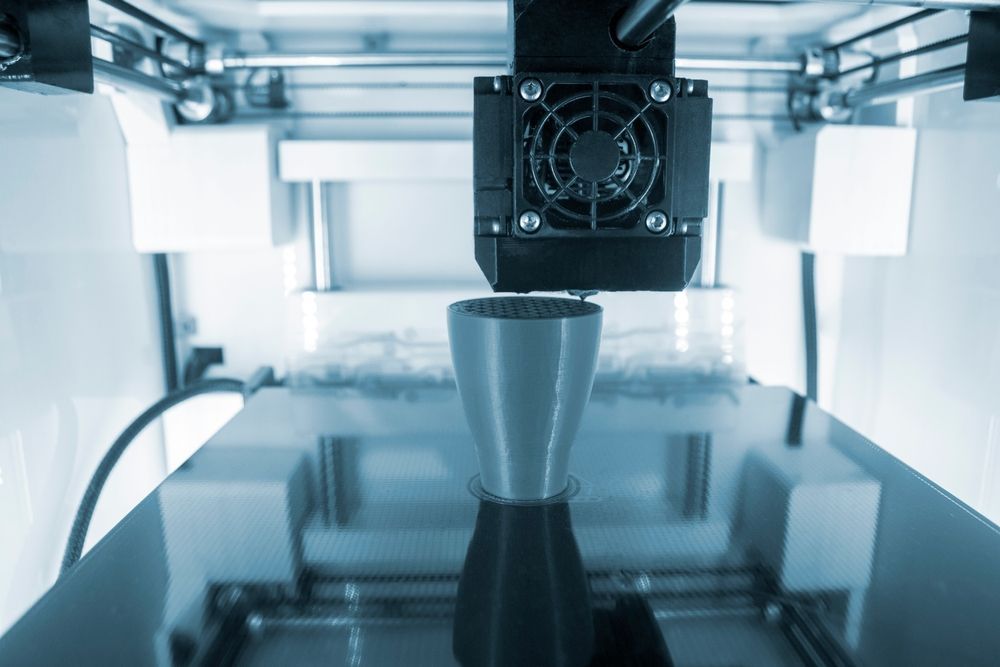

Resin 3D printing delivers high detail and accuracy, but cleaning printed parts remains a challenge. Many professionals still rely on isopropyl alcohol (IPA) and other aggressive chemicals that raise safety, environmental, and regulatory concerns. As the industry evolves, safer and more sustainable cleaning options are becoming a priority.

Different Types of Resin 3D Printer Cleaning Solutions Used

Several solvents are commonly used to clean uncured resin from 3D printed parts. Each comes with its own strengths, drawbacks, and safety considerations. Below is a look at the most frequently used options in the industry.

Isopropyl Alcohol (IPA)

IPA is the most widely used solvent for cleaning resin prints due to its availability, affordability, and effectiveness in dissolving uncured resin. It quickly breaks down liquid resin from printed parts and is compatible with most cleaning stations. However, it is highly flammable, emits strong fumes, and poses health risks with prolonged exposure. Its effectiveness also diminishes over time as it becomes saturated with resin.

Ethyl Acetate (EA)

Ethyl acetate is a fast-evaporating solvent that can effectively clean resin prints. It is less flammable than IPA and has a slightly lower toxicity profile, but it still requires proper ventilation and the use of personal protective equipment (PPE), such as gloves and respirators. EA can also degrade some plastics over time, making it less suitable for cleaning delicate parts or equipment components.

Denatured Alcohol

Denatured alcohol is ethanol blended with additives to make it unfit for consumption. It's often used as a cleaning agent for resin prints due to its strong solvent properties. While effective, it shares many of the same safety concerns as IPA, including flammability and harmful fumes. It also tends to dry out the skin and can cause irritation with repeated exposure, requiring the use of gloves and eye protection.

Acetone

Acetone is a powerful solvent that can dissolve uncured resin quickly, but it is generally too aggressive for most resin prints. It can damage printed parts, cloud surfaces, and degrade plastic components of cleaning equipment. Highly flammable and known for its strong fumes, acetone also poses significant health and safety risks, especially in poorly ventilated areas.

Water-Based Household Cleaners for Cleaning Resin Prints

Water-based household cleaners are sometimes used as a non-flammable alternative for resin cleanup. While it is safer to handle than solvents like IPA or acetone, it is not as effective at breaking down uncured resin. Prints often require longer soak times or additional scrubbing, which can slow down production and reduce consistency in post-processing.

Why IPA Is Most Commonly Used for Resin Printing Cleanup

IPA has become the default cleaning solvent for resin 3D printing because it strikes a balance between cost, availability, and cleaning power. It dissolves uncured resin quickly and evaporates without leaving a residue, making it convenient for post-processing workflows. IPA is also widely compatible with automated wash stations, which adds to its appeal in professional settings.

Despite these advantages, growing concerns around workplace safety, air quality, and hazardous waste disposal have many professionals looking for safer alternatives.

Why Move Away from IPA and Other Harsh Chemicals?

While solvents like IPA, acetone, and denatured alcohol are effective, they come with serious tradeoffs. These include health risks for workers, environmental hazards, and increasing regulatory scrutiny. As safety and sustainability become higher priorities, many in the 3D printing industry are rethinking their cleanup processes.

Health and Safety Risks

Many common solvents used in resin cleanup are flammable and produce harmful fumes. Prolonged exposure to vapors from IPA, acetone, and denatured alcohol can lead to headaches, respiratory irritation, skin damage, and long-term health effects. Frequent handling without proper ventilation or protective gear increases the risk of accidents and chronic exposure in the workplace.

Environmental Impact

Petroleum-based solvents contribute to air and water pollution during use and disposal. Many are classified as volatile organic compounds (VOCs), which release harmful emissions into the atmosphere. Improper disposal can contaminate water systems and soil, while even compliant disposal adds to hazardous waste volumes. As sustainability goals become more central, reducing reliance on these chemicals is a growing priority.

Compliance and Regulatory Considerations (OSHA, EPA)

Workplace safety standards from OSHA and environmental regulations from the EPA place increasing pressure on manufacturers to minimize exposure to hazardous chemicals. Solvents like IPA and acetone are subject to strict handling, storage, and disposal requirements. Companies that fail to comply risk fines, operational disruptions, and damage to their reputation. Safer alternatives can help reduce regulatory burdens while supporting EHS initiatives.

Why Move Away from IPA and Other Harsh Chemicals?

An effective replacement for IPA should offer strong cleaning performance without the health, safety, and environmental risks. Key traits include high resin solvency, low toxicity, non-flammability, and compatibility with existing wash systems. It should also meet regulatory requirements and align with sustainability goals, helping companies reduce hazardous waste and improve air quality without sacrificing efficiency.

Vertec BioSolvents: Your Safer Solution for 3D Printing Cleanup

Vertec BioSolvents offers bio-based alternatives that match the performance of traditional solvents while significantly reducing risk. Formulated from renewable resources like corn and soy, these solvents are non-toxic, low in VOCs, and readily biodegradable. They are designed to work seamlessly in resin 3D printing cleanup, providing effective resin removal without compromising worker safety or environmental standards.

With Vertec BioSolvents, professionals can clean with confidence, knowing their process is safer, compliant, and more sustainable.

Best Practices for Cleaning Resin 3D Prints with Bio-Based Solvents

To get the best results when using bio-based solvents, start by removing excess resin from the print using a soft brush or paper towel. Submerge the part in a solvent bath and agitate gently to help loosen the remaining resin. For larger batches or production environments, automated wash stations can be used with compatible bio-based formulations.

Always follow the manufacturer’s guidelines for soak times and solvent life. Use protective gloves and ensure good ventilation, even with low-toxicity options. After cleaning, rinse the part with clean solvent or water if recommended, then cure as usual.

Make the Safer Switch Today

Traditional solvents like IPA come with serious tradeoffs. Vertec BioSolvents offers bio-based alternatives that are safer for workers, better for the environment, and highly effective at cleaning resin prints. By making the switch, you can improve safety, reduce regulatory risk, and support more sustainable operations.

Explore Vertec BioSolvents’ solutions and upgrade your cleanup process with confidence.